SUBSCRIBE TO OUR NEWSLETTER

Get the latest updates on new products and upcoming sales

Available 24/7 LIVE Chat. Round-the-Clock Live Chat Assistance

Currency

AED

AED

AFN

AFN

ALL

ALL

AMD

AMD

ANG

ANG

AUD

AUD

AWG

AWG

AZN

AZN

BAM

BAM

BBD

BBD

BDT

BDT

BGN

BGN

BIF

BIF

BND

BND

BOB

BOB

BSD

BSD

BWP

BWP

BZD

BZD

CAD

CAD

CDF

CDF

CHF

CHF

CNY

CNY

CRC

CRC

CVE

CVE

CZK

CZK

DJF

DJF

DKK

DKK

DOP

DOP

DZD

DZD

EGP

EGP

ETB

ETB

EUR

EUR

FJD

FJD

FKP

FKP

GBP

GBP

GMD

GMD

GNF

GNF

GTQ

GTQ

GYD

GYD

HKD

HKD

HNL

HNL

HUF

HUF

IDR

IDR

ILS

ILS

INR

INR

ISK

ISK

JMD

JMD

JPY

JPY

KES

KES

KGS

KGS

KHR

KHR

KMF

KMF

KRW

KRW

KYD

KYD

KZT

KZT

LAK

LAK

LBP

LBP

LKR

LKR

MAD

MAD

MDL

MDL

MKD

MKD

MMK

MMK

MNT

MNT

MOP

MOP

MUR

MUR

MVR

MVR

MWK

MWK

MYR

MYR

NGN

NGN

NIO

NIO

NPR

NPR

NZD

NZD

PEN

PEN

PGK

PGK

PHP

PHP

PKR

PKR

PLN

PLN

PYG

PYG

QAR

QAR

RON

RON

RSD

RSD

RWF

RWF

SAR

SAR

SBD

SBD

SEK

SEK

SGD

SGD

SHP

SHP

SLL

SLL

STD

STD

THB

THB

TJS

TJS

TOP

TOP

TTD

TTD

TWD

TWD

TZS

TZS

UAH

UAH

UGX

UGX

USD

USD

UYU

UYU

UZS

UZS

VND

VND

VUV

VUV

WST

WST

XAF

XAF

XCD

XCD

XOF

XOF

XPF

XPF

YER

YER

Couldn't load pickup availability

Our Business Identity & Customer Commitment We are committed to maintaining full transparency in our business practices to ensure a seamless and trustworthy shopping experience for all our customers. Below, we outline key aspects of our operations and policies: ..

🔥 Unlock a 30% discount on your first order using code "PROMO"

🔥 Double up and save—25% off 2 items with code GREATDEAL

🔥 Triple the purchase, triple the savings—35% off 3 items! Use code BARGAIN

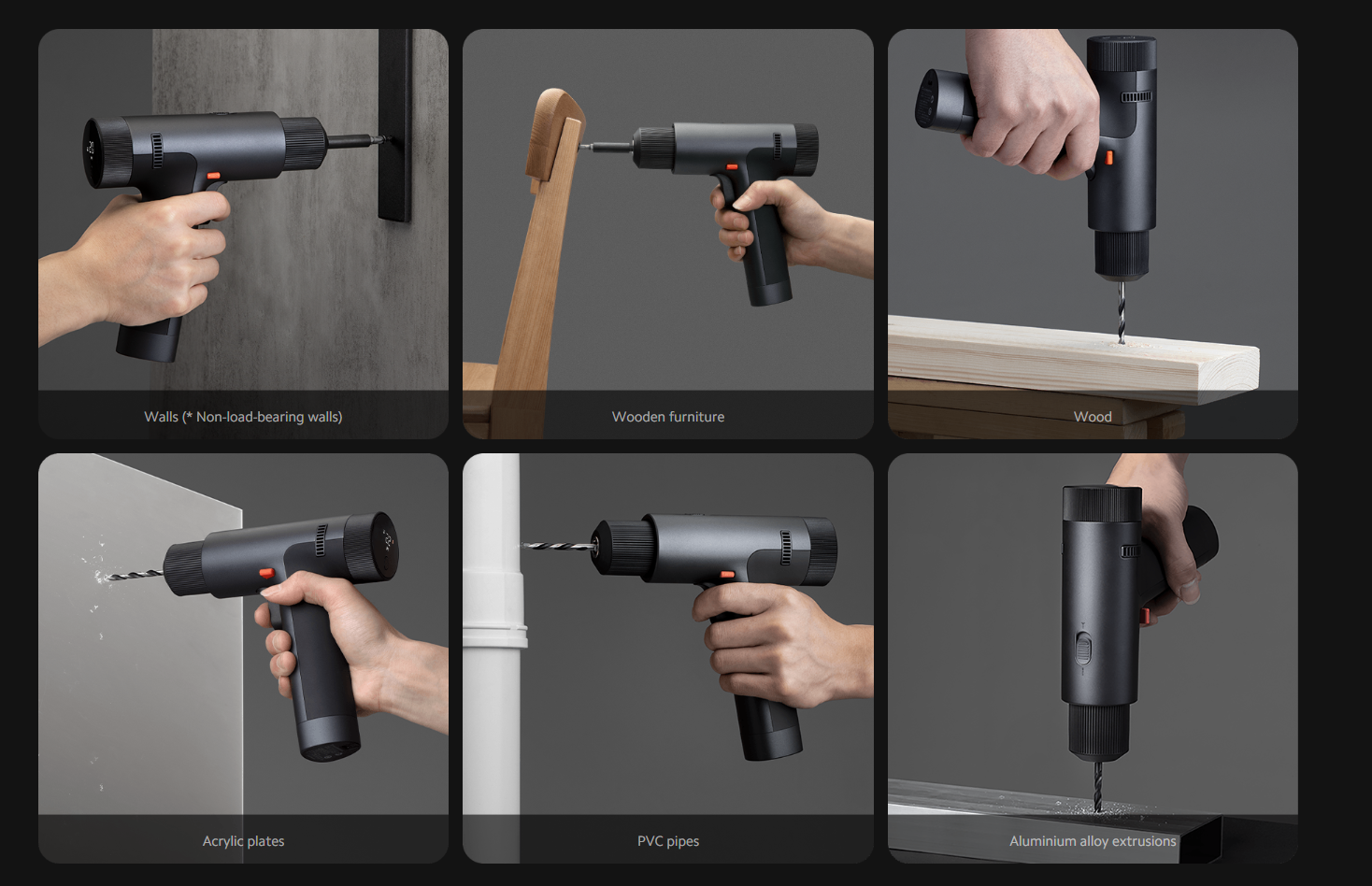

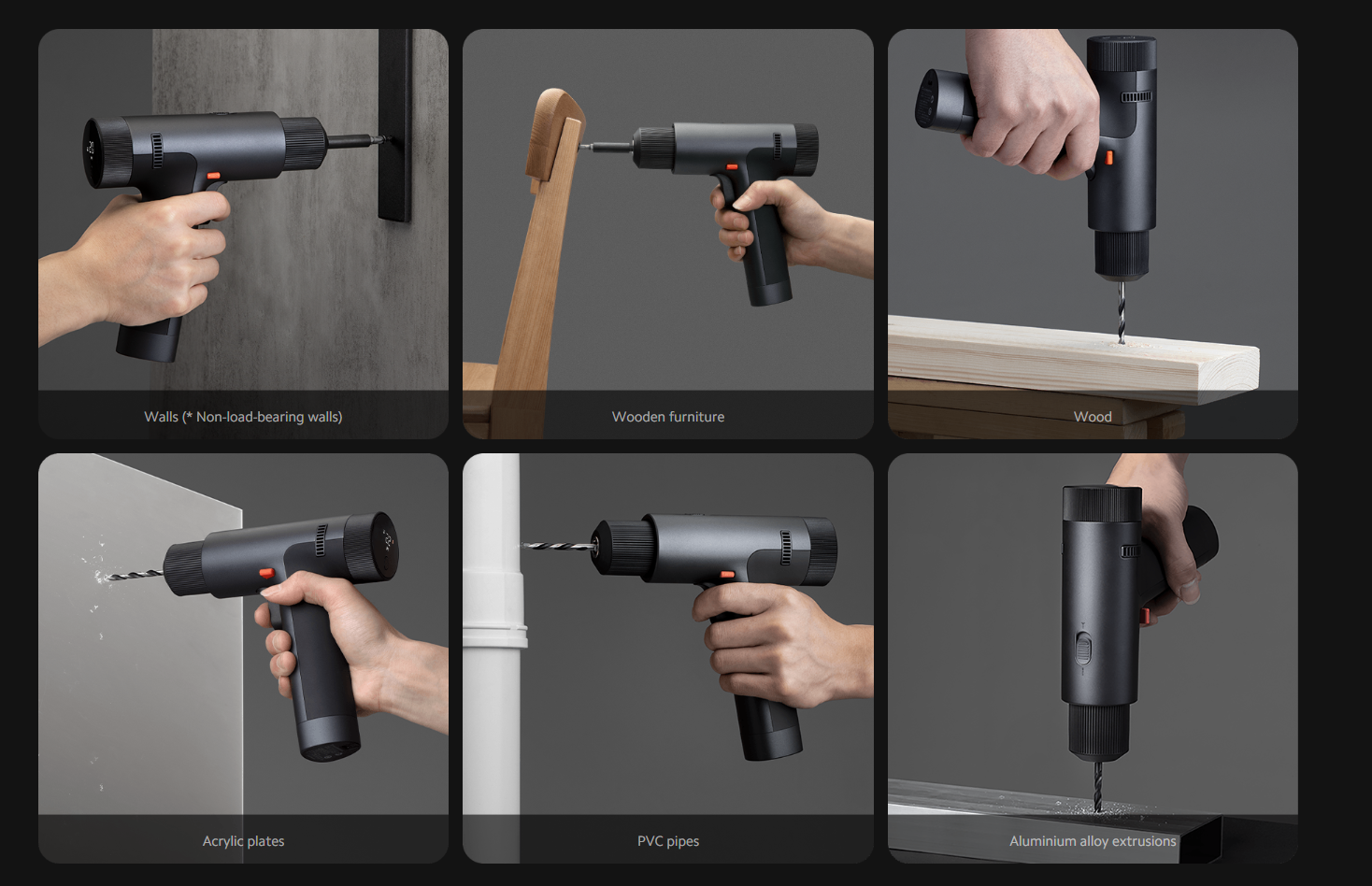

* The maximum torque error is ±5Nm due to the measurement device used. Torque test method: With the battery fully charged, the function selection button is pushed to enter screwing mode. A torque tester is then used to test the locked-rotor torque at level 30.* No-load speed tolerance is approximately 10%. Speed test method: The fully charged device is run for 2 minutes at no load and the no-load speed is then tested with a speed tester.* Screwing test method: With the device fully charged, the gearbox is adjusted to low speed (screwing mode). In manual "M" mode, the tail torque is adjusted to 10 and an M4 x 25mm self-tapping screw is screwed into the pine board until the battery runs out.*Steel plate drilling test method: With the device fully charged, the gearbox is adjusted to the high-speed setting (drilling mode). In M mode, the tail torque is adjusted to 30 and a hole is drilled into a 6mm-thick steel plate with a 6mm twist drill.*Wooden board drilling test method: With the device fully charged, the gearbox is adjusted to the high-speed setting (drilling mode). In M mode, the tail torque is adjusted to 30 and a 40mm-deep hole is drilled into a white pine board with a 7mm wood bit.*The whole unit compliance test report was issued by Waltek Services Test Group Ltd. in Foshan; Test Report No.: WTF21F3015226G.*The whole unit ROHS test report was issued by EMTEK (Dongguan) Technology Co., Ltd.; Test Report No.: ED201110010C.*The EMC test report was issued by EMTEK (Shenzhen) Co., Ltd.; Test Report No.: ES201110017E.*The environmental reliability test report was issued by Intertek Shenzhen Ltd.; Test Report No.: SZHH01513728.*The battery test report was issued by Precise Testing & Certification (Guangdong) Co., Ltd.; Test Report No.: PTC20110204401S-GB01.The screwdriver bit test report was issued by the National Light Industry Tool Hardware Quality Supervision & Testing Station, Shanghai. Test Report No.: G20201629F. Hardness varies by ±2HRC.* Two extension rod designs are available and will be shipped randomly.* The water-repellent fabric test was conducted by Centre Testing International Co., Ltd. and is waterproof up to class 4–5; Test Report No.: A2210085110101C.

| Product Assurance | We take great care in ensuring that all our products meet quality standards and are packaged securely for safe delivery. |

| Requirement Analysis | performance benchmarks |

| Manufacturing & Production Control | Implemented quality checks during production |

| Compliance | Keeping up with evolving regulations. |

Get the latest updates on new products and upcoming sales

Thanks for subscribing!

This email has been registered!